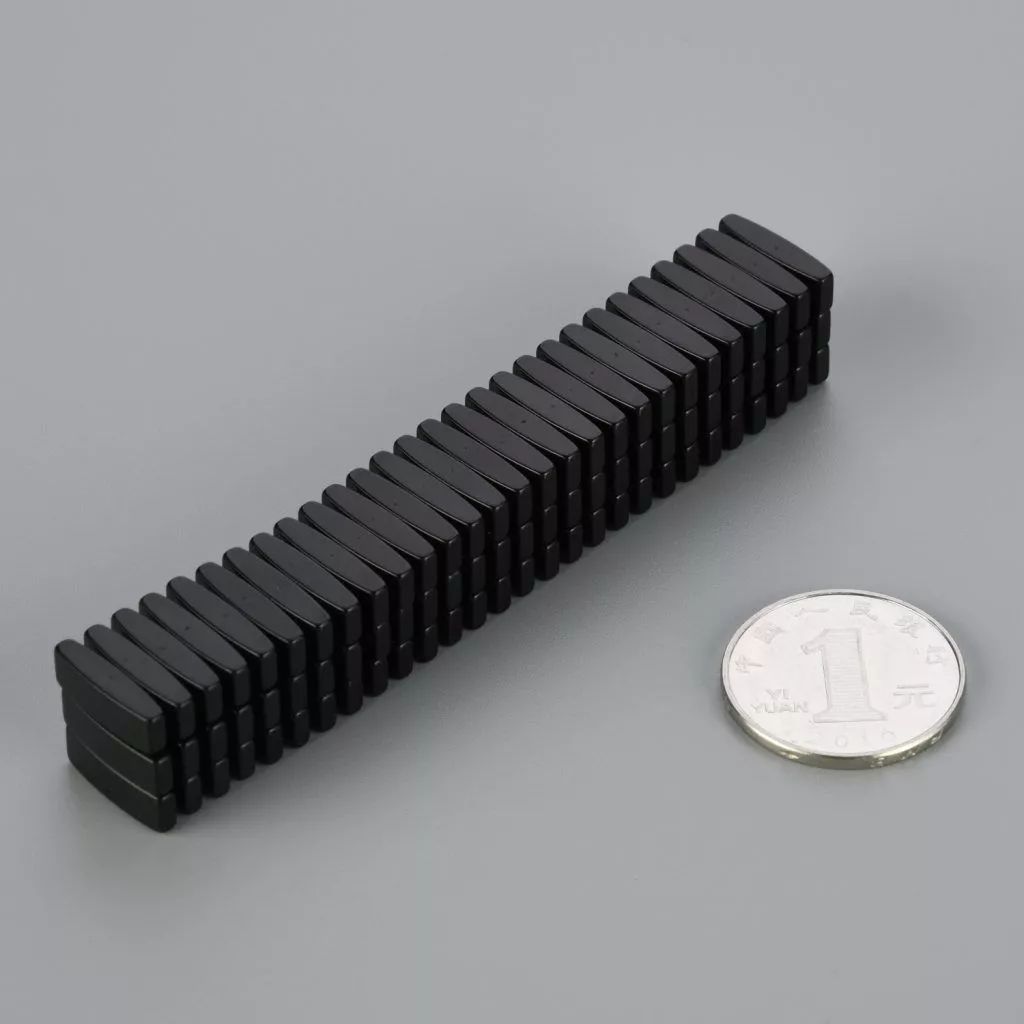

Neodymium Magnet

Neodymium magnets are known as super magnets, which is a kind of rare earth magnets, they have extraordinary strength even at their smallest size and are among the strongest permanent magnets in the world. The magnetic material of our super-strong magnets is an alloy consisting of neodymium, iron and boron (NdFeB). Neodymium magnets are used for a wide range of applications, from cabinetry, lighting systems, plastics technology and packaging materials to the construction of models.

Send Inquiry

Neodymium magnets are known as super magnets, which is a kind of rare earth magnets, they have extraordinary strength even at their smallest size and are among the strongest permanent magnets in the world. The magnetic material of our super-strong magnets is an alloy consisting of neodymium, iron and boron (NdFeB). Neodymium magnets are used for a wide range of applications, from cabinetry, lighting systems, plastics technology and packaging materials to the construction of models.

| MAGNETIC CHARACTERISTICS AND PHYSICAL PROPERTIES OF SINTERED Nd-Fe-B | |||||

| PROPERTIES | BnnT(KGs) | Hcb KA/m (Koe ) | Hcj KA/m (KOe) | (BH)max KJ/m³(MGOe) |

TW ℃ |

| GRADE | |||||

| N33 | 1130-1170 (11.3-11.7) | ≥836 (≥10.5) | ≥955 (≥12) | 247-263 (31-33) | 80 |

| N35 | 1170-1210 (11.7-12.1) | ≥868 (≥10.9) | ≥955 (≥12) | 263-287 (33-36) | 80 |

| N38 | 1210-1250 (12.1-12.5) | ≥899 (≥11.3) | ≥955 (≥12) | 287-310 (36-39) | 80 |

| N40 | 1250-1280 (12.5-12.8) | ≥923 (≥11.6) | ≥955 (≥12) | 302-326 (38-41) | 80 |

| N42 | 1280-1320 (12.8-13.2) | ≥923 (≥11.6) | ≥955 (≥12) | 318-342 (40-43) | 80 |

| N45 | 1320-1380 (13.2-13.8) | ≥876 (≥11.0) | ≥955 (≥12) | 342-336 (43-46) | 80 |

| N48 | 1380-1420 (13.8-14.2) | ≥835 (≥10.5) | ≥876 (≥11) | 366-390 (46-49) | 80 |

| N50 | 1400-1450 (14.0.14.5) | ≥796 (≥10.0) | ≥876 (≥11) | 382-406 (48-51) | ≤60 |

| N52 | 1430-1480 (14.3 14.8) | ≥796 (≥10.0) | ≥876 (≥11) | 398-422 (50-53) | ≤60 |

| N35M | 1170-1220 (11.7-12.2) | ≥868 (≥10.9) | ≥1114 (≥14) | 263-287 (33-36) | ≤100 |

| N38M | 1220-1250 (12.2-12.5) | ≥899 (≥11.3) | ≥1114 (≥14) | 287-310 (36-39) | ≤100 |

| N40M | 1250-1280 (12.5-12.8) | ≥923 (≥11.6) | ≥1114 (≥14) | 302-326 (38-41) | ≤100 |

| N42M | 1280-1320 (12.8-13.2) | ≥955 (≥12.0) | ≥1114 (≥14) | 318-342 (40-43) | ≤100 |

| N45M | 1320-1380 (13.2-13.8) | ≥995 (≥12.5) | ≥1114 (≥14) | 342-366 (43-46) | ≤100 |

| N48M | 1360-1430 (13.6-14.3) | ≥1027 (≥12.9) | ≥1114 (≥14) | 366-390 (46-49) | ≤100 |

| N50M | 1400-1450 (14.0-14.5) | ≥1033 (≥13.0) | ≥1114 (≥14) | 382-406 (48-51) | ≤100 |

| N33H | 1130-1170 (11.3-11.7) | ≥836 (≥10.5) | ≥1353 (≥17) | 247-271 (31-34) | 120 |

| N35H | 1170-1210 (11.7-12.1) | ≥868 (≥10.9) | ≥1353 (≥17) | 263-287 (33-36) | 120 |

| N38H | 1210-1250 (12.1-12.5) | ≥955 (≥11.3) | ≥1353 (≥17) | 287-310 (36-39) | 120 |

| N40H | 1240-1280 (12.4-12.8) | ≥963 (≥11.6) | ≥1353 (≥17) | 302-326 (38-41) | 120 |

| N42H | 1280-1320 (12.8-13.2) | ≥955 (≥12.0) | ≥1353 (≥17) | 318-342 (40-43) | 120 |

| N45H | 1300-1360 (13.0-13.6) | ≥963 (≥12.1) | ≥1353 (≥17) | 342-358 (43-46) | ≤120 |

| N48H | 1370-1430 (13.7-14.3) | ≥995 (≥12.5) | ≥1353 (≥17) | 358-390 (46-49) | ≤120 |

| N33SH | 1130-1170 (11.3-11.7) | ≥844 (≥10.6) | ≥1592 (≥20) | 247-272 (31-34) | 150 |

| N35SH | 1170-1210 (11.7-12.1) | ≥876 (≥11.0) | ≥1592 (≥20) | 263-287 (33-36) | 150 |

| N38SH | 1210-1250 (12.1-12.5) | ≥907 (≥11.4) | ≥1592 (≥20) | 287-310 (36-39) | 150 |

| N40SH | 1240-1280 (12.4-12.8) | ≥839 (≥11.8) | ≥1592 (≥20) | 302-326 (38-41) | 150 |

| N42SH | 1240-1320 (12.8-13.2) | ≥987 (≥12.4) | ≥1592 (≥20) | 318-342 (40-43) | ≤150 |

| N45SH | 1320-1380 (10.2-10.8) | ≥1003 (≥12.6) | ≥1592 (≥20) | 342-366 (43-46) | ≤150 |

| N28UH | 1020-1380 (10.2-10.8) | ≥764 (≥9.6) | ≥1990 (≥25) | 207-231 (26-29) | 180 |

| N30UH | 1080-1130 (10.8-11.3) | ≥812 (≥10.2) | ≥1990 (≥25) | 223-247 (28-31) | 180 |

| N33UH | 1130-1170 (11.3-11.7) | ≥852 (≥10.7) | ≥1990 (≥25) | 247-271 (31-34) | 180 |

| N35UH | 1180-1220 (11.8-12.2) | ≥860 (≥10.8) | ≥1990 (≥25) | 263-287 (33-36) | ≤180 |

| N38UH | 1220-1250 (12.2-12.5) | ≥876 (≥11.0) | ≥1990 (≥25) | 287-310 (36-39) | ≤180 |

| N40UH | 1240-1280 (12.4-12.8) | ≥899 (≥11.3) | ≥1990 (≥25) | 302-326 (38-41) | ≤180 |

| N28EH | 1040-1090 (10.4-10.9) | ≥780 (≥9.8) | ≥2388 (≥30) | 207-231 (26-29) | 200 |

| N30EH | 1080-1130 (10.8-11.3) | ≥812 (≥10.2) | ≥2388 (≥30) | 223-247 (28-31) | 200 |

| N33EH | 1130-1170 (11.3-11.7) | ≥836 (≥10.5) | ≥2388 (≥30) | 247-271 (31-34) | ≤200 |

| N35EH | 1170-1220 (11.7-12.2) | ≥878 (≥11.0) | ≥2388 (≥30) | 263-287 (33-36) | ≤200 |

| N38EH | 1220-1250 (12.2-12.5) | ≥899 (≥11.3) | ≥2388 (≥30) | 287-310 (36-39) | ≤200 |

REMARKS:

※The above-mentioned data of magnetic parameters and physical properties are given at room

temperature.

※The maximum service temperature of magnet is changeable due to the ratio length and diameter and

environmental

factors.

※Density: 7.4-7.6g/cm'; aBr: -0.09-0. 13%/*C; aHq;: -0.50--0.80%/C; Hardness: Hv 600 ;

Sintering

Stifle

Grinder

Multi-line cutting

When packing NdFeB magnets, it is important to use materials that provide sufficient protection without affecting the magnetism of the magnets. Soft materials such as foam and cardboard are ideal for packing neodymium magnets as they provide cushioning and absorb any shock that may occur during transportation.

How to Safely Seperate Your NEW-MAG Magnets?

CORRECT

1. Slide one magnet off the top of the stack.

2. Once off thestack,carefully start lifting the magnet.

3. Lift the magnet to free it from the stack.

INCORRECT

1. DO NOT attempt to pull, lift, or pry a magnet from the stack before sliding it to the side.

2. DO NOT throw away the white storage spacers.

3. DO NOT allow the magnets to snap to each other or any magnetic surface. doing so may cause

magnets to

break!